A new lightweight, impact-resistant technology inspired by a tiny crustacean could change the way we play sports, and also improve wind-farm productivity and automotive fuel economy.

The technology, which creates material with a structure that resembles twisted plywood, has been developed by David Kisailus, professor of chemical and environmental engineering, as well and materials science and engineering at the University of California, Riverside. The license was acquired by Helicoid Industries Inc.

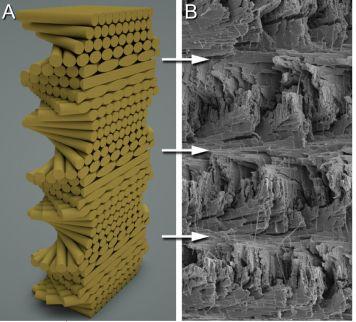

Millions of years ago, the "smasher" mantis shrimp, one of nature's feistiest predators, evolved an internal structure to protect the hammer-like club it uses to pulverize prey with incredible speed and force. The unique structure, called a helicoid, wraps within the mantis shrimp's club and protects it from damage as it delivers crushing blows to its hard-shelled prey.

In the mantis shrimp, the helicoid prevents cracks from growing and ultimately dissipates significant amounts of energy from strikes to avoid catastrophic failure. It achieves immense impact resistance without adding unnecessary weight. Kisailus and his team discovered manufacturing ultrastrong composite materials and components using this helicoid structure results in lighter, tougher, and more impact-resistant products.

Helicoid Industries hopes to sublicense the technology to the sporting goods, wind turbine, aerospace, auto parts, defense, and industrial components industries. The impact in the sporting goods industry could be significant, where weight of equipment is an issue.

However, the biggest impact could be felt in wind-turbine manufacturing, where the lower energy production costs of larger blades are offset by limitations imposed by their increased weight. Helicoid composite materials would make larger, more lightweight blades and improve the efficiency and cost-effectiveness of wind-based energy production.

UC Riverside’s Office of Technology Partnerships, or OTP, leads technology transfer, industry partnership, and entrepreneurship efforts for the university. The integrated OTP team, including intellectual property and commercialization experts, mentors from EPIC SBDC, the office’s Small Business Development Center, and scientists worked closely with Helicoid Industries to support the licensing and fundraising process to ensure a successful venture.

“We are delighted to partner with Helicoid Industries to commercialize this unique technology, so it can positively impact society,” said Rosibel Ochoa, associate vice chancellor of technology partnerships at UC Riverside.

“Utilization of this bio-inspired technology will enable composites to be lighter weight, more impact-resistant, more durable, and be manufactured at a lower overall cost. Applying this new architecture into composite materials across a variety of sectors will be very beneficial to the composite industry,” said Chad Wasilenkoff, CEO of Helicoid and a seasoned entrepreneur with 25 years of experience in acquiring and building over 30 global companies in various industries.

The company is finalizing a $5 million financing round to build its management and sales teams and to complete prototype manufacturing.

The company envisions commercialization before the end of 2019.