The fashion industry produces far more inventory than it sells, consuming and polluting more of the planet’s resources than necessary and generating about 10% of the world’s greenhouse gas emissions. Much of this excess merchandise ends up in landfills or is burned, prolonging the environmental assault.

Mass customization, where customers order clothing made to their own style tastes and measurements, has been proposed as one solution to overproduction. But the logistical challenges of tailoring garments to individual customer requests and lengthy manufacturing lead times have discouraged most firms from adopting mass customization. They might want to reconsider that decision, according to a new study co-authored by a UC Riverside researcher. Forthcoming in Manufacturing and Service Operations Management, the study suggests that under the right circumstances, mass customization can generate higher profits and reduce environmental waste considerably.

Customers willing to wait for bespoke clothing from a company that both mass produces and mass customizes garments can make the fashion industry more environmentally sustainable, but only when overproduction is really a problem, reports the study, coauthored by Adem Orsdemir, a professor of operations and supply chain management in UCR’s School of Business. Government policies that make recycling or disposal more expensive for companies boost the sustainable effect in certain situations.

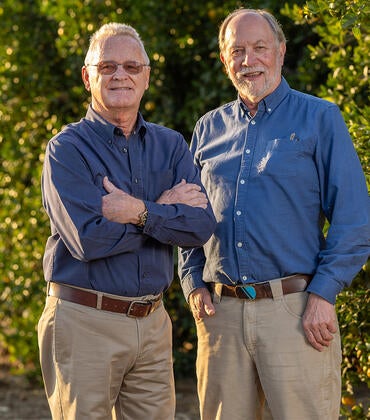

Orsdemir and co-author Aydin Alptekinoglu at Pennsylvania State University developed an analytical model of a mass production firm that went hybrid by also adopting mass customization. The researchers modeled product variety, price, and inventory decisions the firm makes to maximize its profits.

They found that when customers could be persuaded to wait longer for customized garments, the benefit of mass customization increased unambiguously. The benefit also unambiguously increased when policymakers targeted high disposal fees or costly recycling programs at firms with a low cost of product variety, such as fast-fashion brands like H&M, to deter overproduction and targeted firms with a high cost of product variety, such as most luxury brands, to acquire technology that would make recycling profitable.

In some cases, the conflicting demands of mass production and mass customization caused the firm to overproduce. For example, a hypothetical denim company mass produces a quantity of jeans that usually sell out each season. Some people switch to custom, increasing overall production and making the environmental impact worse. For hybrid mass customization and mass production to be profitable for the firm as well as environmentally beneficial, companies need to strike a balance between the two production modes.

“If you can promote it as a sustainable way of producing fashion goods and increase the customer’s patience with waiting, mass customization is more likely to become a win-win,” said Orsdemir.

Before adopting mass customization however, companies need to consider that the practice can ultimately make overproduction worse and sustainability an even more elusive goal than it already is.

“Mass customization can be helpful or hurtful,” said Orsdemir. “The bottom line is it’s helpful when there’s a lot of overproduction. Mass customization can improve that. But when overproduction isn’t really a problem, mass customization can make overproduction worse.”

Though their work focused on the fashion industry, the authors think their findings could also apply to other industries where overproduction creates environmental problems.

The paper, “Is adopting mass customization a path to environmentally sustainable fashion?” has been accepted for publication in Manufacturing and Service Operations Management, a top journal hosted by INFORMS and is available on the SSRN preprint server here.