In order for metal nanomaterials to deliver on their promise to energy and electronics, they need to shape up — literally.

To deliver reliable mechanical and electric properties, nanomaterials must have consistent, predictable shapes and surfaces, as well as scalable production techniques. UC Riverside engineers are solving this problem by vaporizing metals within a magnetic field to direct the reassembly of metal atoms into predictable shapes. The research is published in The Journal of Physical Chemistry Letters.

Nanomaterials, which are made of particles measuring 1-100 nanometers, are typically created within a liquid matrix, which is expensive for bulk production applications, and in many cases cannot make pure metals, such as aluminum or magnesium. More economical production techniquess typically involve vapor phase approaches to create a cloud of particles condensing from the vapor. These suffer from a lack of control.

Reza Abbaschian, a distinguished professor of mechanical engineering; and Michael Zachariah, a distinguished professor of chemical and environmental engineering at UC Riverside’s Marlan and Rosemary Bourns College of Engineering; joined forces to create nanomaterials from iron, copper, and nickel in a gas phase. They placed solid metal within a powerful electromagnetic levitation coil to heat the metal beyond its melting point, vaporizing it. The metal droplets levitated in the gas within the coil and moved in directions determined by their inherent reactions to magnetic forces. When the droplets bonded, they did so in an orderly fashion that the researchers learned they could predict based on the type of metal and how and where they applied the magnetic fields.

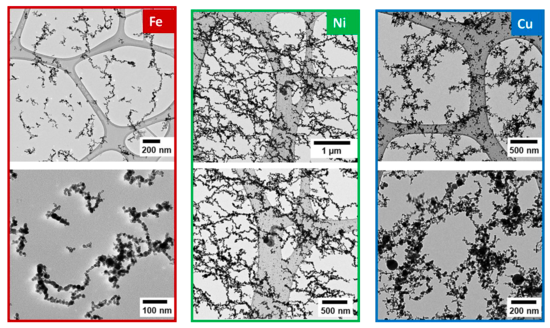

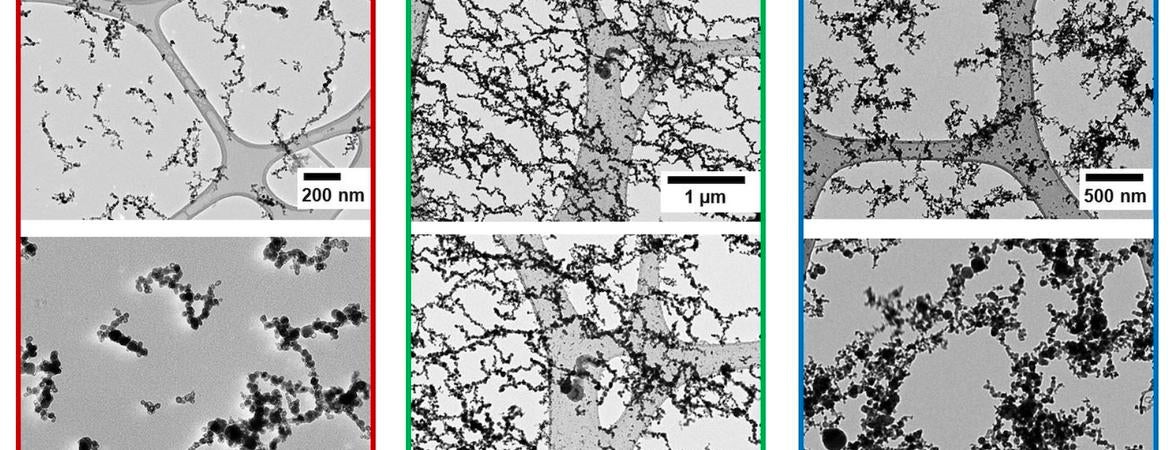

Iron and nickel nanoparticles formed string-like aggregates while copper nanoparticles formed globular clusters. When deposited on a carbon film, iron and nickel aggregates gave the film a porous surface, while carbon aggregates gave it a more compact, solid surface. The qualities of the materials on the carbon film mirrored at larger scale the properties of each type of nanoparticle.

Because the field can be thought of as an “add-on,” this approach could be applied to any vapor-phase nanoparticle generation source where the structure is important, such as fillers used in polymer composites for magnetic shielding, or to improve electrical or mechanical properties.

“This ‘field directed’ approach enables one to manipulate the assembly process and change the architecture of the resulting particles from high fractal dimension objects to lower dimension string-like structures. The field strength can be used to manipulate the extent of this arrangement,” Zachariah said.

Abbaschian and Zachariah were joined in the research by Pankaj Ghildiyal, Prithwish Biswas, Steven Herrera, George W. Mulholland, and Yong Yang. The paper, “Magnetic-field directed vapor-phase assembly of low fractal dimension metal nanostructures: experiment and theory,” is available here.