A new material, created at the little-explored intersection of organic and inorganic chemistry, could not only enable more powerful solar panels, but it could also usher in the next generation of cancer treatments.

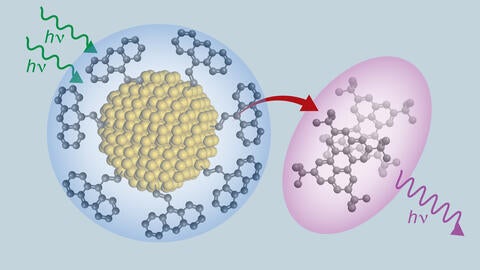

Described in a Nature Chemistry journal paper published today, the composite is made of ultra-tiny silicon nanoparticles, and an organic element closely related to those used in OLED televisions. It is capable of increasing the speed with which two molecules can exchange energy, and of converting lower-energy light into higher-energy light.

Only a handful of laboratories in the world are capable of making the silicon nanoparticles with the right specifications. One of those laboratories is led by Lorenzo Mangolini, a mechanical engineering and materials science professor at UC Riverside who helped invent the process for producing them.

“The new material improves on previous attempts we’ve made to create something that efficiently exchanges energy between two dissimilar components,” Mangolini said. “There are great opportunities to use this for a wide variety of applications, but perhaps one of the most important, from a human health perspective, is for cancer.”

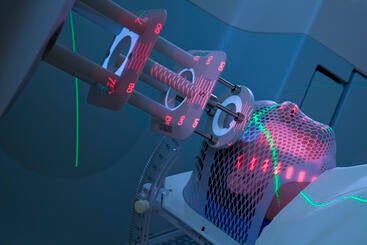

High-energy light, such as ultraviolet laser light, can form free radicals able to attack cancer tissue. UV light, however, doesn’t travel far enough into tissues to generate therapeutic radicals close to the tumor site. On the other hand, near-infrared light penetrates deeply into the body, but doesn’t have enough energy to generate the radicals.

With the new material, the research team has demonstrated it is possible to achieve the emission of light with higher energy than the one aimed at the material, known as photon up-conversion. In addition to being efficient, the silicon “dots” that form the base of this high-energy material are not toxic.

Taking low-energy light and transforming it into a higher energy form could be used to boost the efficiency of solar cells by allowing them to capture near-infrared light that would normally pass through them. When optimized, the low-energy light could reduce the size of solar panels by 30%.

“These cells usually don’t use low-energy photons, but using this system, you could. We could make the arrays much more efficient,” Mangolini said.

There are a variety of applications involving infrared light that could be improved with the new silicon dot-based material. They include bioimaging, light-based 3D printing, and light sensors that would help self-driving cars through foggy weather.

This research was funded by the National Science Foundation and was performed by a team based at the University of Texas, Austin, University of Colorado, Boulder, and the University of Utah, as well as UCR. Not only is the research team excited about the potential applications, but about being able to design a new class of composite materials like this one.

Composites are materials that behave differently than their base components do when acting alone. As an example, composites of carbon fibers and resins are strong and lightweight and are used in airplane wings and many sporting goods.

“We now know how to take two extremely different substances and bond them strongly enough to create not just a mixture, but an entirely new material with distinct properties,” said Sean Roberts, University of Texas at Austin chemistry professor and corresponding paper author. “This is one of the first times this has been achieved.”

(Cover image: Mark Kostich/iStock/Getty)